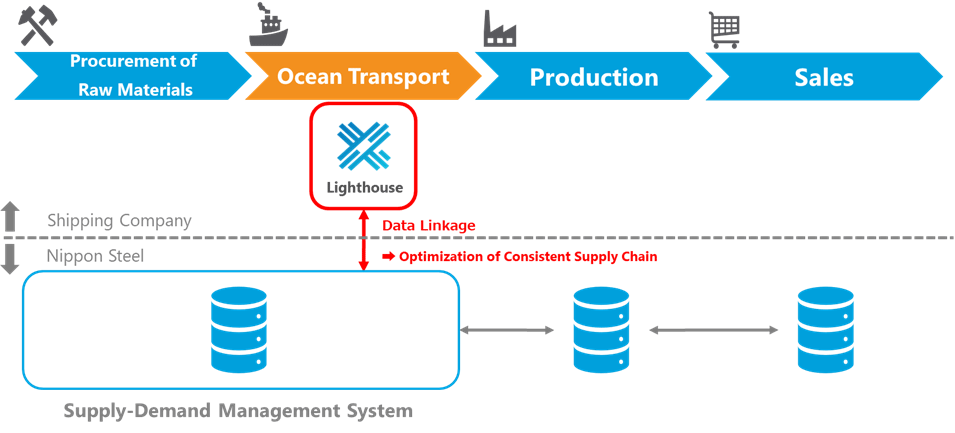

Mitsui O.S.K. Lines, Ltd. announced the launch of an inter-system linkage between “Lighthouse”, a platform developed for bulkship customers to provide information on ocean transport, and the supply-demand management system of Nippon Steel Corporation.

Lighthouse is a service that allows those involved in the transport process, such as shippers and vessel operators, to safely, unitarily, and in real time, share and monitor various kinds of information related to ocean transport, such as vessel schedules, weather, ocean conditions, as well as data related to cargoes and contracts, on a customized basis for each customer.

Until now, Nippon Steel obtained information on ocean transport in raw material procurement through information sharing from various shipping companies, including MOL with a limited frequency. Linking Nippon Steel’s supply-demand management system with Lighthouse enables the customer to constantly monitor and update a broad range of information on ocean transport, such as schedules and cargo information, not only for MOL-operated vessels, but also those of other shipping lines, allowing the conversion of more information into useful data.

MOL will use data and digital technology to help customers optimize their supply chains, not only in ocean transport, but also throughout the entire supply chain from raw material procurement to production, and to transform their business models for the better. Then, it aims to reduce the environmental impact of ocean transport and achieve net-zero greenhouse gas emissions by improving service and quality based on customer needs, by, for example, enhancing operational and transport efficiency.

MOL Group will continue to earn the trust of a wide range of stakeholders while offering high-quality transport services and new added value through the use of digital technology as a group.