A “battery megatrend” has been gathering force for years on a global scale, first in electronic devices with the maturing of Li-ion battery technology and then in large devices such as automobiles. It’s part of a huge global effort to increase sustainability and reduce CO2 emissions. Konecranes is doing its part in the container handling industry, taking the lead as a container handling equipment and service supplier. Konecranes offer large container handling machines that are battery-driven: the Konecranes Battery RTG, the Battery Konecranes Noell Straddle Carrier, and all-electric Konecranes Gottwald Generation 6 Mobile Harbor Cranes. This is the next step in the evolution of Ecolifting, only from Konecranes.

Some container handling equipment is “small” in industry terms, an example being a reach stacker, a type of heavy-duty lift truck that handles containers weighing up to 40 tons when full. Some container handling equipment is large, such as a Rubber-Tired Gantry (RTG) crane, in size around 23m wide and some 27m tall, running on rubber tires. RTGs work in the container yards of seaport container terminals, taking containers in and out of the container stacks, and “shuffling” them there as needed. Many container terminals use RTGs as their container yard workhorses, and Konecranes is a leading world supplier of RTGs. Konecranes also offers automated RTG systems, which are becoming increasingly popular. Making an RTG run successfully on batteries is a considerable engineering challenge: it’s a large machine doing heavy work at a fast pace, usually 24/7.

World’s first! Battery-driven RTG

We now offer the Konecranes RTG with battery power in addition to the cable reel and busbar electric power options. The Konecranes Battery RTG can be thought of as a system when it is operated with a charging station. This will always be the case when the Konecranes Battery RTG is automated. It can also be operated manually, with manual plug-in for charging. This brings new flexibility and “no strings”1 electric operation to RTG-based container yards, as well as zero local CO2 emissions and virtually zero local noise emissions. Combine this with the fact that the Konecranes Battery RTG is delivered in a carbon neutral state, and we get the most eco-efficient RTG in history.

Electric experience

Konecranes started the battery trend in container handling equipment with the introduction of a battery-driven Automated Guided Vehicle some 15 years ago. The battery AGV earned acceptance and became established in large fleets at major container terminals. Meanwhile, a transition from lead-acid to Li-ion battery technology occurred, which was a major leap forward. Konecranes has been learning enormously about battery technology and electric power management over the years. This knowledge has been used to introduce battery AGVs, hybrid RTGs and a battery-driven forklift truck, the E-VER. Then the time came to introduce battery-driven, large container handling machines. When all-electric machines are charged with renewable energy, we call it “pure electric” since it’s the purest form of container handling to date.

Battery Konecranes Noell Straddle Carrier

Straddle carriers are specialized machines that handle containers, running on rubber tires, that are used in “straddle carrier container terminals” around the world. Straddle carrier terminals use straddle carriers as their primary container handling machine. In operational terms they are very flexible. They run on rubber tires and do most of the container handling work in the terminal, running between the quayside and container yard.

Konecranes Gottwald Generation 6 all-electric Mobile Harbor Cranes

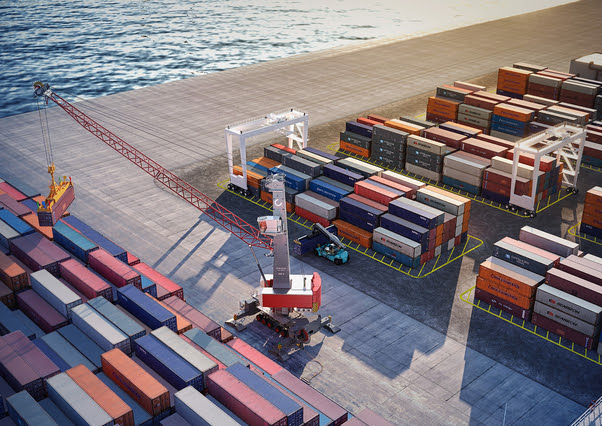

Mobile Harbor Cranes are a general-purpose crane type that is very popular at ports around the world because it can handle containers, bulk cargo and general cargo. It’s a mobile crane type as its name implies: it can be moved on rubber tires to different locations around the port as needed, taking on different types of jobs.

In June of last year, Konecranes introduced Konecranes Gottwald Generation 6 Mobile Harbor Cranes (MHCs). It has been enthusiastically received by the market, especially the modular drive system. This includes the all-electric drive, combining an external power supply with an innovative battery drive. The world’s first all-electric Konecranes Gottwald MHC with battery drive is already working hard at the Port of Skellefteå in Sweden. It is helping to supply an ultramodern battery factory in the town of Skellefteå. In addition, two all-electric Konecranes Gottwald ESP.9 MHCs, each with 200 t maximum lifting capacity, will enter operation at the Port of San Diego, USA, in spring 2023.

A strong focus on customers and a commitment to business growth and continuous improvement make Konecranes a lifting industry leader. This is underpinned by investments in digitalization and technology, plus our work to make material flows more efficient with solutions that decarbonize the economy and advance circularity and safety.