What is Outbound Logistics?

Outbound logistics is a term for the processes of storing, moving and distributing goods. It includes all systems that help prepare an order and get it to the end customer.

The different stages are warehousing and storage, distribution, transportation, and last-mile delivery.

Let’s take a more in-depth look at the individual areas of outbound logistics:

1. Warehousing and storage

To meet demand as you make continued sales, you need to keep a surplus of products in storage. In January 2020, US companies had, on average, a ratio of 1.39 inventory to monthly sales.

The goal of warehousing is to keep products safe and readily available while awaiting purchase. You can store products in your own warehouse or one that is owned by a third-party logistics provider.

2. Inventory management

Inventory management involves picking, packing, and storing your goods in the right place. Many warehouses have inventory management systems to help with this.

3. Transportation

Next, is the process of shipping products to distribution centers/partners. At this stage, transportation is typically done by big trucks/planes/freights. The long distances and large volumes can be a challenge.

4. Last mile delivery

Last mile delivery is the most important step, and is also the most expensive. This is when your order goes from the distribution center to your customer’s door. This task is typically handled by a large fleet of smaller trucks or vans.

If you sell direct to consumer, for example, from an e-commerce store or catalog, you need to cover these four stages effectively.

From managing the product in your warehouse to preparing the parcel and passing it on to a freight service, and delivering the final goods, every stage impacts whether the order gets to the customer’s door on time.

Just think of everything that happens behind the scenes so Amazon can offer same-day delivery from online sales.

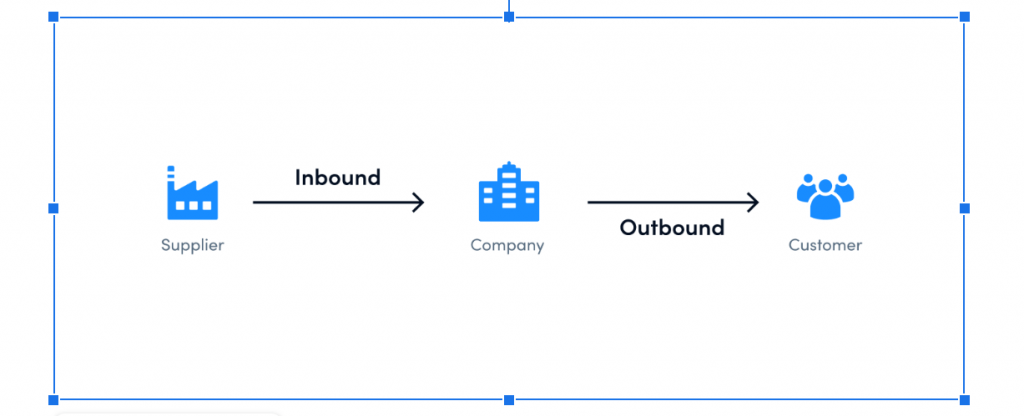

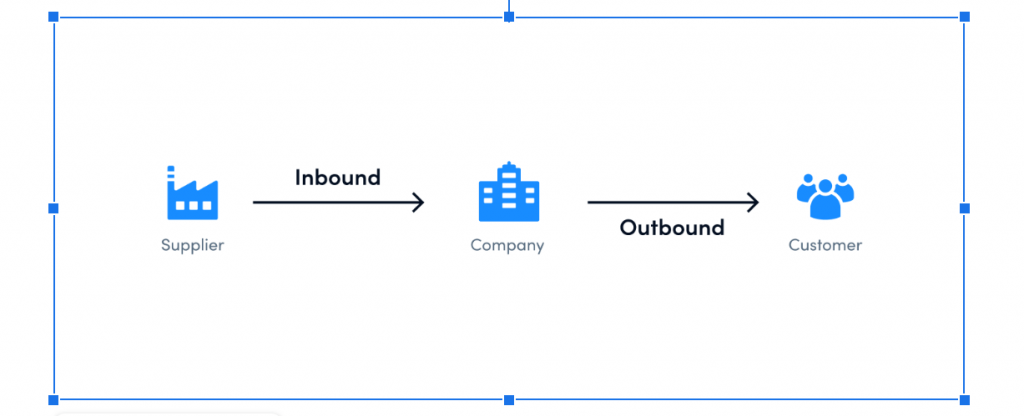

What Is the Difference Between Inbound and Outbound Logistics?

The key difference between inbound and outbound logistics is simple: Inbound logistics refers to all processes related to getting your products from your suppliers and manufacturers — products coming in. It includes sourcing, buying, storing, and distributing goods and supplier returns.

On the other hand, outbound logistics is all about delivering products to customers — orders going out. It includes inventory management, order management, packing, distribution, and more.

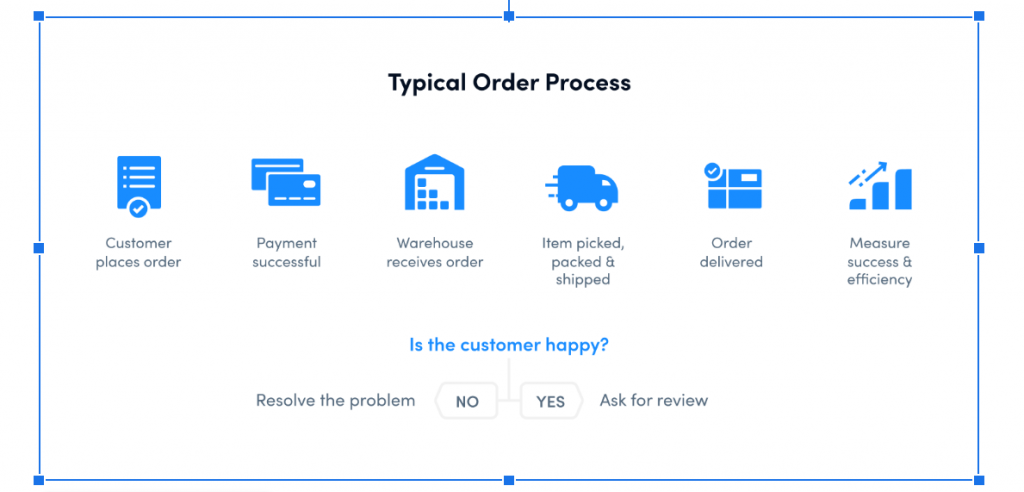

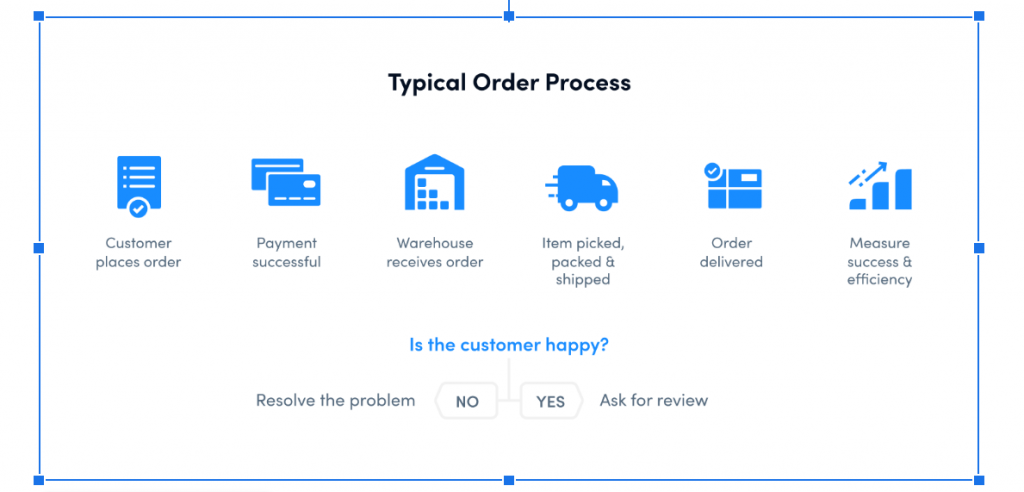

An Example of the Outbound Logistics Process

In this section, we will cover an example of an outbound logistics order process.

Let’s examine every stage for an e-commerce company that sells consumer products.

1. Customer places order

The customer places an order for a specific product on your e-commerce site or through your catalog.

2. Order is confirmed, and products picked in the warehouse

The warehouse confirms the ordered products, the workers pick the relevant inventory. If in place, the WMS system adjusts product counts based on the product id or stock-keeping unit (SKU).

3. Order is packed at warehouse

Workers in the warehouse pack the products and prepare them for shipping by moving them to the loading dock.

4. Trucks pick up daily orders

Freight trucks pick up the orders bound for the relevant distribution centers every day.

5. Trucks drive to distribution centers

The trucks drop off the ordered inventory at the closest distribution center to the customer.

6. Delivery drivers pick up orders at distribution centers

Delivery drivers pick up individual orders at distribution centers for their delivery area.

7. The package is delivered to the customer

The package arrives at the doorstep of the customer, completing the logistics process.

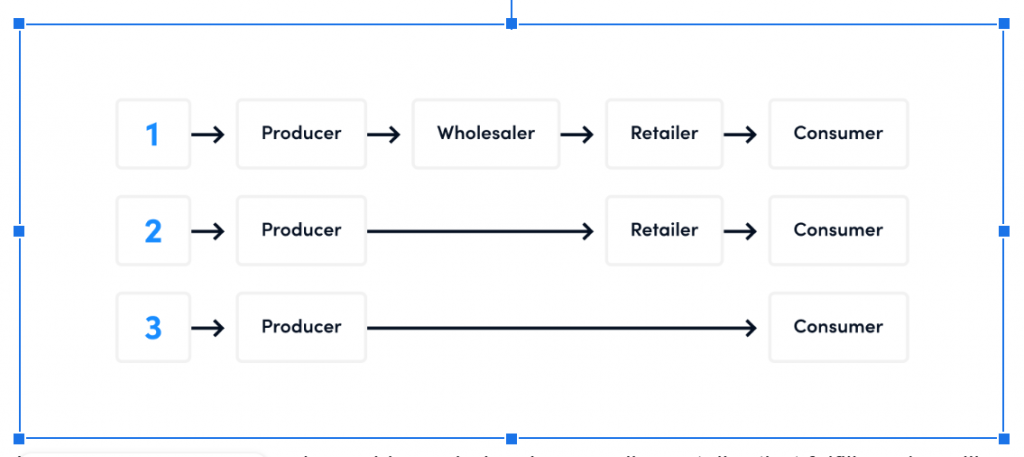

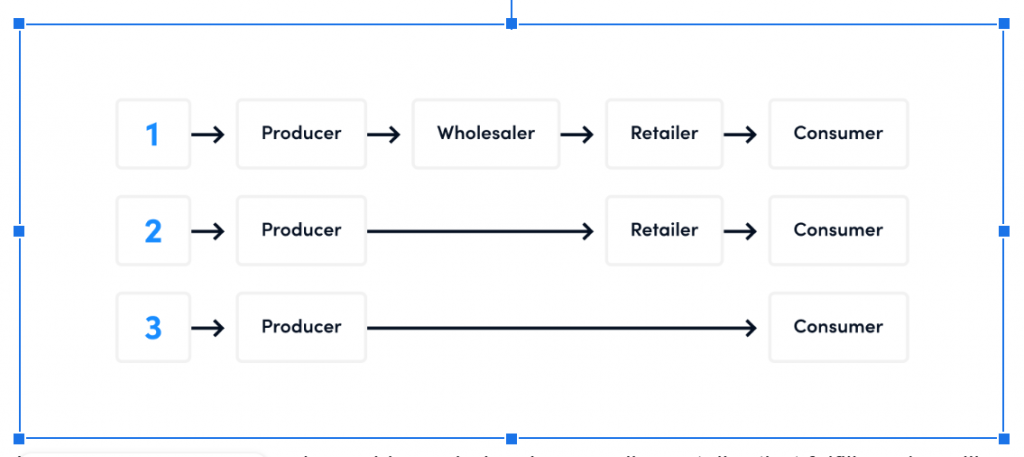

Channels of Distribution

Businesses that don’t sell straight to consumers, don’t handle the entire outbound logistics chain.

If your main distribution channel is a wholesaler or online retailer that fulfills orders, like Amazon FBA, it’s a different story. Your main concern isn’t optimizing each stage of the process. You need to pick reliable wholesalers, distributors, or retailers and develop strong relationships with them.

Work closely with supply-chain partners

The tail end of supply-chain management is a critical part of your outbound logistics. So if you don’t handle everything yourself, make sure you work closely with retailers or third-party distributors.

An excellent example of collaboration is P&G and Walmart’s supply-chain partnership. They share data and coordinate real-time adjustments to meet the changing demands of the consumer goods market.

A good way to kickstart a partnership can be to coordinate advertising efforts. If you show an interest in improving the bottom line for your retailers or wholesalers, they’ll be more interested in your products.

Outbound Logistics and Delivery Directly Impacts the Customer Experience

It doesn’t matter if you sell consumer products or customized solutions for businesses. Outbound logistics plays a big part in customer satisfaction for manufacturers or online retailers.

And 81% of companies single out customer experience as a competitive advantage.

Below, we’ve listed the top three criteria for meeting customer expectations and keeping them happy.

These three areas are essential to meeting and exceeding customer expectations and ensuring return business in the long term.

1. On-time delivery is essential

It’s 2020. With Amazon leading the pack with same-day delivery, you can no longer afford delayed shipments and packages.

Every hour your package is delayed is another burden on the customer relationship. To succeed in e-commerce, it’s not enough to promise fast delivery, you must keep that promise.

2. Delivering to the wrong address is unacceptable

What’s worse than getting a package late? Not getting the package at all because it was mishandled and sent to the wrong place.

3. The product must arrive in an acceptable condition

If the product is delivered on time, but it’s in an unusable or severely damaged condition, your customer won’t be happy. It’s an even worse experience than a delayed delivery.

If you use a third-party logistics provider, you must pick a trustworthy one.

This article originally appeared on optimoroute.com